NEW! Velox Miter 5-Axis CNC Machine

The New Velox Miter adds another CNC machine to the current Pade Range lineup. Its design makes it ideal to do joinery required for stiles

5-Axis CNC Machining and work centers for the Woodworking and Advanced Materials Industries

The New Velox Miter adds another CNC machine to the current Pade Range lineup. Its design makes it ideal to do joinery required for stiles

Chrono 5 axis CNC Precise, Fast & Reliable 5-Axis Workcenter The 5-axis Chrono is precise, fast, and reliable yet it is affordable even for smaller

Vario TR 5-Axis CNC Machining Center Featuring Rotating Work Table with Two Working Stations VARIO TR is a machining centre with overhead 5-axis and mobile

Vario TT 5-Axis CNC Work Center Featuring Two Workbenches and a Mobile Crossbeam VARIO TT is a machining work center with overhead 5 axes and

Clipper – 5 axis CNC Designed for Precise, Complex & High-Speed Machining Operations on Wood & Advanced Materials The CLIPPER L is the open beam

Chrono Duet – 5 axis CNC Double CNC 5+5 Axis Work Center to Maximize Flexibility Maximum flexibility and highest productivity: now possible with CHRONO DUET,

UINZE CNC Profile Shaping & Sanding Machine for Producing Solid Wood Components The UINZE CNC linear shaping and sanding machine is the ideal solution for

SPIN Mould Fixed Bridge, Moving Table Work Center SPIN MOULD is a fixed bridge – moving table work center. It can be ordered with one

MILL 5-Axis CNC Work Center Ideal for Manufacturing of Complex Parts Made of Solid Wood and Advanced Materials For the Production of Complex Parts Made

Velox 5-Axis CNC Precise and Complex Machining Operations on Wood & Advanced Materials The Velox incorporates an overhead open beam design (fixed bridge-moving tables). Motor

Velox Miter Machine to Miter Cabinet Components The Velox Miter has been designed specifically, but is not limited, to do the joinery required for stiles

Suitable for Cutting Laminated Wooden Panels and Other Materials with Regular Shapes and Size Without Any Defects

Band Saw Designed to Handle All Types of Wood, including Rough Cut Solid Wood Boards with Defects, Laminated Panels, or Other Similar Materials

CNC Machining Center – MZ Pluris Band Saw System, 3 Axis High-Speed Electro Spindle for Routing

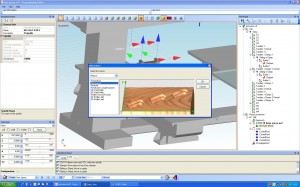

e-Lab is a powerful tool that works together with your CAM software after the program is posted to the machine or it can also be used independently allowing you to program simple parts from drawing files without dedicated CAM software.

Remote Service & Diagnostics: With “PADE DIRECT”, you, the customer, can receive assistance direct by remote link. Pade or Pade USA will be in a position

Copyright © PADE USA · 5-Axis CNC Machining Work Centers · Multi-Axis Manufacturing Machines for Woodworking · Non-Ferrous Metals · Plastics · Acrylics · Advanced Materials · Parts & Service · Login